The general requirements for the structure of industrial plugs are:

(1) Devices are prone to incorrect connections and the surface should be free of burrs, burrs, and similar sharp edges to ensure safe manual operation.

(2) The screws or other parts used for fixing components should be easily visible for easy assembly and fixation.

(3) Users cannot change the position of the ground level or central pole that is not interchangeable to ensure proper installation.

(4) Set positioning keys to ensure precise insertion positions.

(5) Set up a retention device to prevent detachment after insertion.

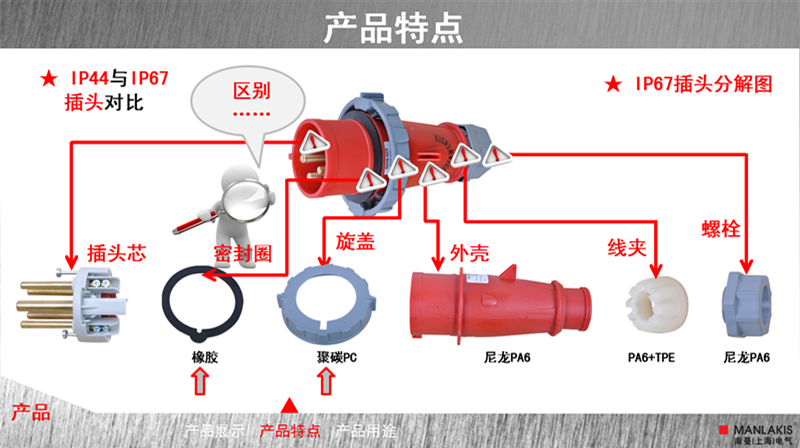

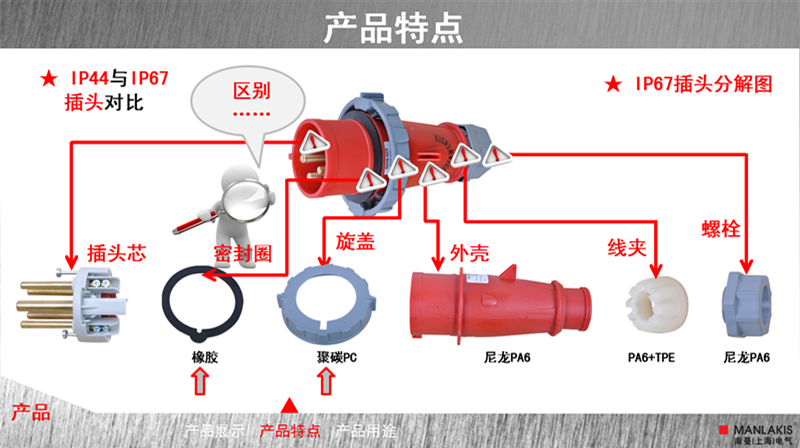

(6) The structure should be able to achieve the specified protection level:

1) Electrical accessories with rated currents of 16, 32, and 63A have splash proof (IP44) and immersion proof (IP67) structures.

2) 125A electrical accessories should be of the anti immersion type (IP67) structure.

3) When the 125A socket is installed on the casing or integrated with the casing, the entire unit can be of an anti immersion (IP44) structure.

(7) The inverted camera mechanism should have a locking mechanism to maintain its position, prevent accidental movement, and its action should not damage cables and wiring.